Spraytecs In-Line Filters are a family of products suitable for many industry processes where accurate performances are mandatory.

This range of industrial filters has been introduced on request by our customers, that need of reliable performances, stop nozzles clogging and correct dimensioning of filters in their particular applications.

Here below are shown filters and accessories, where datasheet is complete and contain the most important information for the plant designer, to obtain the lowest drop losses and the best results.

Moreover a Mesh (screen dimension for stop particles) conversion table between different standards and sizes is here below, to help to select the range of filtering is required by your application.

Our In-Line filters are suitable for two different ways of use:

A) for fixed installations (filter cartridge can be cleaned alone, without dismount the filter by the circuit), with bigger size than filters for mobile applications.

B) for mobile installations (filter must be dismounted to clean the internal cartridge), with a compact body when related to the typical flow rate

Contact us for any question or special requirement.

Special filters on customer's requirement are possible, starting by the current available models.

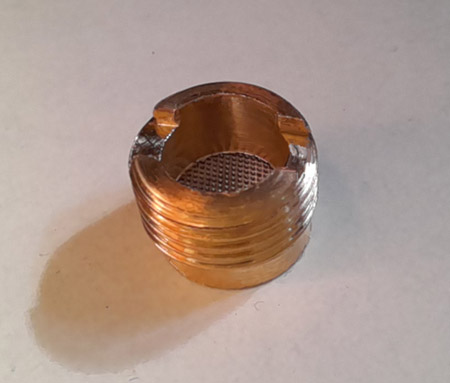

Filter model A:

internal filter for nozzles, suitable both for fixed and mobile installations.

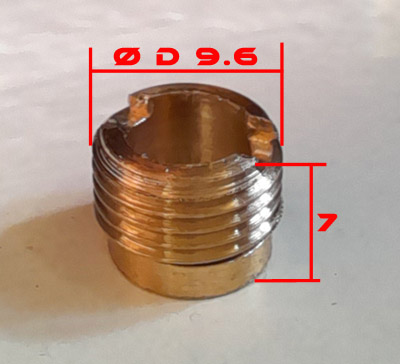

Filter model B:

internal filter for nozzles, very compact and not visible outside nozzle, suitable both for fixed and mobile installations.

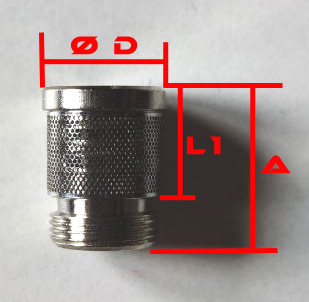

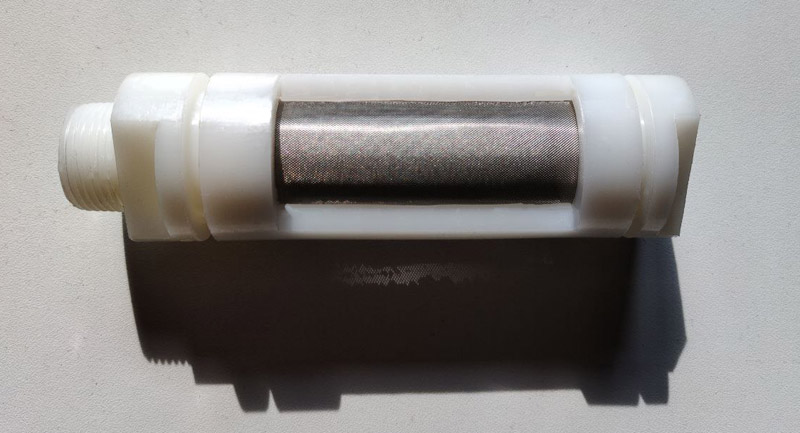

Filter model Y:

external filter, suitable for fixed installations.

Filter model M:

external filter, suitable for mobile installations.

Ask for further information by email about your next Spraytecs filter!

Check with SPRAYTECS for critical dimension, pressure, capacity, fluids in your applications, in order to receive support in your decision.

Nozzle materials must meet correctly chemical composition of fluids in your processes, always remember it.

Spray angle performance varies with pressure. Contact SPRAYTECS for specific data on your critical applications.