These SPRAYTECS nozzles produce a flat spray characterized by a low flow rate and small size droplets.

The flat jet is formed by the concentration of small drops at the nozzle outlet (orifice) , which form angles of different amplitudes according to the parameters of the project.

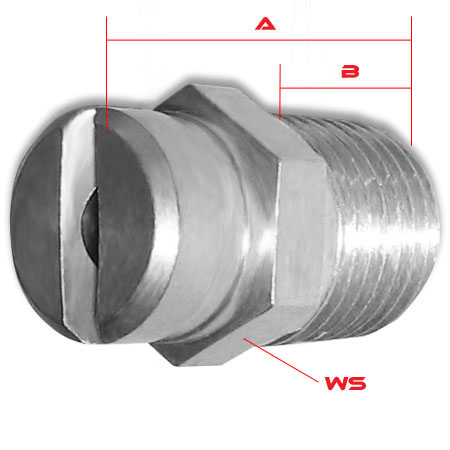

In this case, the spray is produced on the same line with respect to the axis of the feed tube of the nozzle, then defined "axial" .

The droplets produced by these nozzles SPRAYTECS are of small diameter, with spray angles between 25 ° and 110 °, obtained by means of the adoption of a special form of orifice, which determines flow rate and droplet size.

These flat jet nozzles have a high efficiency and a low flow rate, this means that employ a small amount of fluid to obtain the spray angles of the desired coverage.

They have not good resistance to occlusions, because their minimum free passage is quite small. It is therefore recommended to use clean fluids, not containing suspended parts that can affect the functionality of the nozzle.

To obtain the certainty of a good service of these SPRAYTECS nozzles, the use of fluids without impurities is recommended. This may be obtained with the adoption of a system of adequate filtering of the fluids which must be used by these nozzles.

These spray nozzles are suitable for the following applications :

- manufacturing processes in the pharmaceutical and chemical industry,

- humidification of environments and plants,

- sanitization and disinfection of environments and foods ,

- aerospace industry

Note that these SPRAYTECS nozzles are available in brass in all ranges of this section, and in stainless steel only in the flow rates indicated in the tables.

The picture on the left shows the spray pattern of these nozzles

Check with SPRAYTECS for critical dimension, pressure, capacity, fluids in your applications, in order to receive support in your decision.

Nozzle materials must meet correctly chemical composition of fluids in your processes, always remember it.

Spray angle performance varies with pressure. Contact SPRAYTECS for specific data on your critical applications.