Spraytecs SACS (SPRAYTECS ATOMIZERS CONTROL UNIT) are a family of friendly electronic Control Units to drive, control, improve, automate your fluid based systems.

SACS Control Units can work stand-alone, or can interact with other process machines, CNC machines and Host computers, directly linked or wi-fi linked.

SACS are available in a scalable range of features, with inside basic or powerful electronic Control Unit and a list of devices as electronic driven valves, sensors, manometers, leds, displays, all with a common detail: the high quality and high value of every single component, to offer a superior reliability 24/7 of continuous service.

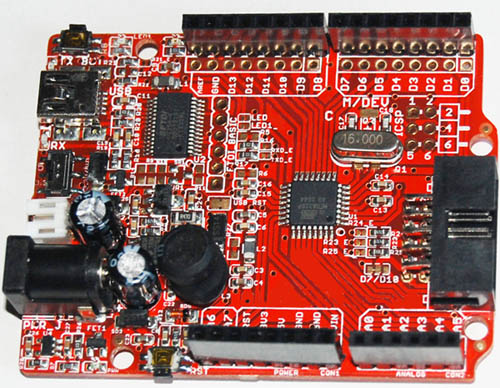

The Spraytecs SACS microprocessor based "brain"

SACS are designed to improve your fluid based system, and give a quick solution in a part of your whole industrial process, with components designed and tested to work together, as already experienced sub-system ready to install and work.

SACS can help both Purchase Department and R&D Dept. because can represent a local solution in a single detail of the process when one, two or more different fluids (air, gas, liquids, powders) must work with one or many nozzles, air atomizers, hydraulic atomizers. Work means quick time to atomize fluids, spray and stop, vary the percentages mix between fluids, cool, wet or dry a product during manufacturing, and so on.

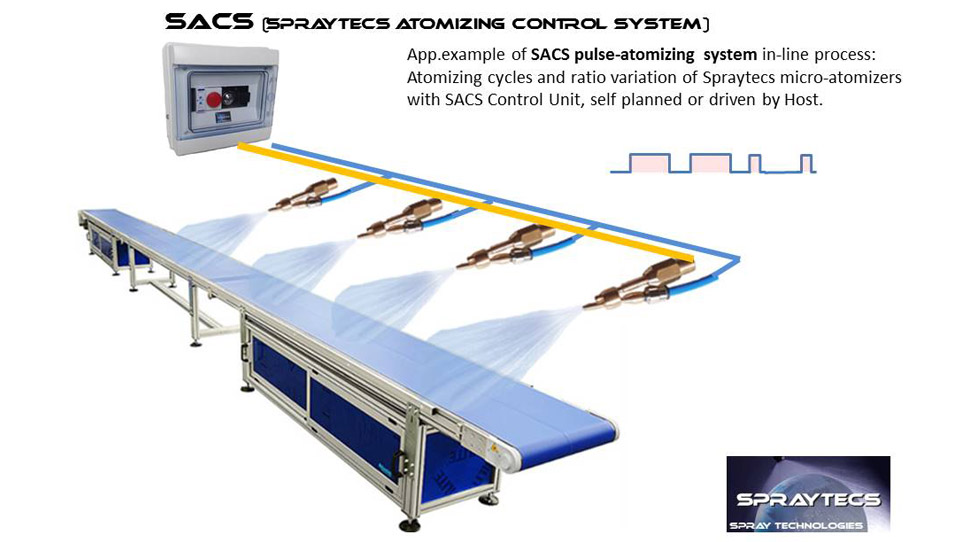

Here below a basic example of application driven by a SACS Control Unit:

The liquid fluid, must be atomized in the compressed air flow, is added only in precise time intervals, repeated in a continuous cycle as shown in the squared waveform in the right. The SACS Control Unit produces a pulse-width modulation, in few words it changes the atomizer flow rate through a fractionation in time intervals of the liquid fluid added in the air flow, through a rapid response solenoid valve . This principle gives the feature to share the nominal atomizer flow rate in a smaller real flow rate in each atomizer in the process line, and moreover both droplets size and spray shape remain the same.

This operation (in the process above shown) can be executed from the SACS at start-on, or changed during the process time by an external machine or a remote link (Wi-Fi), depending from SACS model installed.

SACS Control Units have different dimensions and weight of case or rack, depending from the version and the number of functions must be performed by the SACS model.

All SACS Control Units are very easy to install, with user manual instructions and some examples. They are powered with DC current with any voltage in the range between 12V d.c. and 24V d.c.

SACS can close or open each fluid flow line in only 20 ms, maintain this state for a minimum of 100 ms (20 ms in a special version) or per hours and then change again to the previous state in only 20 ms.

Both fluid flow Close and Open state time length are mutually independent, therefore the resulting duty cycle of each fluid channel time diagram is totally defined by the engineer, without limits about percentages of ON/OFF state.

Max environment temperature range -10°/+50°, Max fluids temperature range +0°/+130°, Max viscosity 37 cStokes (5°E).

Please contact Spraytecs to request the SACS functions you need in your process.

Moreover:

Ask us for price, performances and other information about that products.

Check with SPRAYTECS for critical dimension, pressure, capacity, fluids in your applications, in order to receive support in your decision.

Nozzle materials must meet correctly chemical composition of fluids in your processes, always remember it.

Spray angle performance varies with pressure. Contact SPRAYTECS for specific data on your critical applications.